Recovery Systems

Clemco

We offer a variety of media recovery solutions to meet your needs.

-

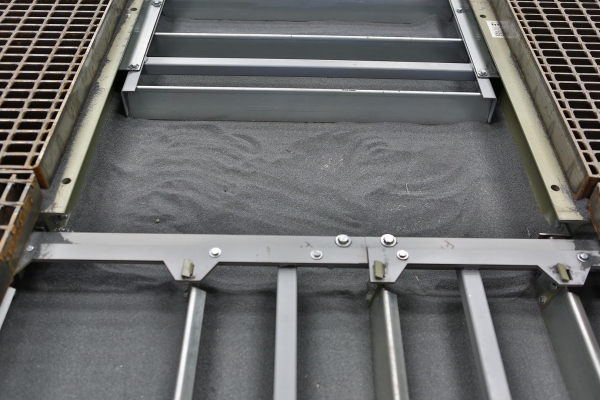

Belt Conveyor Systems

- The Clemco BCR system features multiple floor collection hoppers installed in a trench in the blast room floor. Partial-area systems can be configured in a single run, in H-, L-, or

U-patterns or whatever layout suits the appliction. Floor gratings, flush with the blast room floor, cover the hoppers. Abrasive falls through the grating, into the hoppers, through a

metering tube, falling on the 12-inch wide belt below. The distance between the hopper metering tube and the conveyor belt is set for the optimal media flow-rate which prevents belt overload.

- The Clemco BCR system features multiple floor collection hoppers installed in a trench in the blast room floor. Partial-area systems can be configured in a single run, in H-, L-, or

-

Flat-Trac Systems

- Rugged steel vanes, suspended within a pneumatically powered frame, push the media forward. The pneumatic drive cylinder delivers up to 440 pounds of force to easily push the heaviest steel abrasives. As the frame moves back, the vanes ride up over the back into position for the forward push. The cross drive module, operating on the same level as the floor modules, carries the media to the bucket elevator. Adjustable electro-pneumatic cycle timers allow complete control of feed rates for all floor modules and cross drive modules. By adjusting the feed rates, the Flat-Trak® floor can keep pace with two full-time blast operators using 3/8-inch nozzles, at 100 psi.

-

Screw Conveyor

- Designed primarily for use with steel grit and shot, Clemco’s screw conveyor recovery module with bucket elevator can continuously reclaim up to 180 cubic feet of media per hour. Because they are used most often with steel grit and shot, most screw recovery modules are mounted in a pit so the heavy media can be pushed into them with skidloaders or other methods.

-

Hopper Systems

- The hopper and bucket elevator recovery systems process up to 180 cubic feet per hour of dense and coarse media, such as steel grit and shot. With the 3 ft x 3 ft hopper system, flush mounting requires a pit just 4 1/2 feet deep. Where a high water table prevents excavation, the smaller 2 ft x 2 ft system can be wall-mounted and shovel fed.

-

M Sections

- Clemco’s standard Sweep-In M-Section Pneumatic Recovery Systems efficiently recover and recycle most medium and low-density blast media, such as glass bead, plastic, and aluminum oxide. The recovery section can be placed in a shallow channel, just 10″ deep, for a true sweep-in operation, or surface mounted where conditions will not allow excavation.

-

MB Vacuums

- Munkebo Portable Abrasive Vacuum and Recycling Systems efficiently remove and recycle spent abrasive, are low-maintenance, and help you increase productivity.

UniWest

UniWest