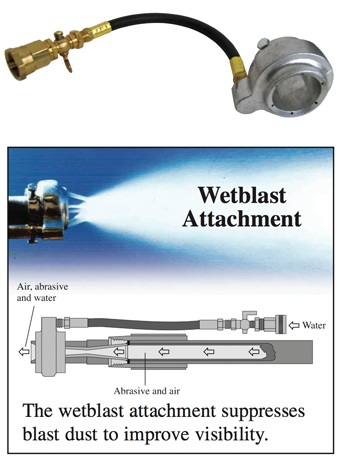

Clemco WetBlast Water Ring

Eliminates About 80% of Dust Without Lowering Blast Efficiency

The Clemco Wetblast Attachment easily mounts to the barrel of a blast nozzle to quickly give a dry blast machine Wetblast capability. It is uniquely suited for jobs in metropolitan areas or in awkward or confined spaces where a larger machine may be impractical, or for jobs with lower dust output that would not require the Wetblast FLEX™ or Wetblast Injector.

A rust inhibitor is recommended when using the attachment to Wetblast steel surfaces. The inhibitor may be sprayed on the blast surface immediately after blasting or can be mixed in a water tank equipped with a pump and sprayed through the Wetblast Attachment head during blasting.

Design Advantages

The Wetblast Attachment head is equipped with locking screws for mounting to the barrel of a nozzle. Six 3/32″ water jets then surround the nozzle and direct water to spray at a point 3 inches in front of the nozzle. As the water hits the air-abrasive stream, it atomizes to envelop the abrasive particles. This process creates a creates a uniform water spray, a larger blast pattern, and prevents stoppages that occur with systems that mix or carry an abrasive-water slurry through the blast hose.

The water volume is metered by a full-flow petcock located at the blast head. Pressure ranges of 30 lbs to 60 lbs (city water pressure) are acceptable. Hose fittings attach to a standard water hose or faucet, and a 50 ft x ¼” ID water hose is available for use with the Wetblast Attachment head.

UniWest

UniWest